Terahertz Applications of the TeraSense Technology in Ceramic Tiles Industry

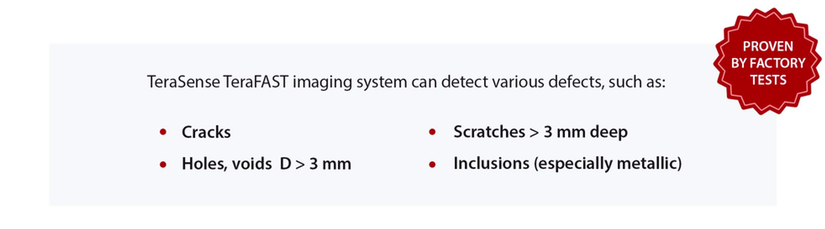

The high speed linear terahertz scanning system manufactured by TeraSense for conveyor belt applications is a highly effective solution for non-destructive test and quality control of various materials in an industrial environment. A key benefit of the TeraSense THz imaging technology is its high sensitivity to multiple features and inclusions in the volume of non-metallic materials (ceramics, plastics, wood) which makes it suitable for evaluation of density and humidity variations in the pressed powders (‘green tiles’ and kiln fired tiles in the ceramic industry; pills, caplets and tablets in the pharmaceutical industry, etc.).

One of the important aspects in the ceramic tile production is to monitor density gradients in ‘green’ tiles right after being formed in a press and examine finished tiles for various defects. Unlike the X-Ray technology, the TeraSense THz imaging is highly sensitive to density deviations and especially to moisture content of ceramic samples. The TeraSense technology is your instrument to monitor density deviations in a tile right from the forming press and to provide feedback for a powder feeding machine.

Advantages of the THz imaging system:

- High image acquisition rate (up to 5000 fps)

- Non-destructive (no ionizing radiation)

- Powerful tool for defects inspection in dry tiles

- Powerful tool for measuring density or humidity variations in wet tiles

- Low cost solution

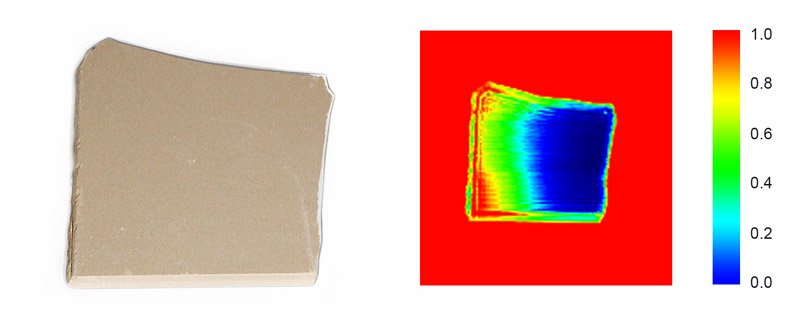

Pic.1 THz transmission image of a 'green' ceramic tile with a strong moisture gradient (0 to 3%).

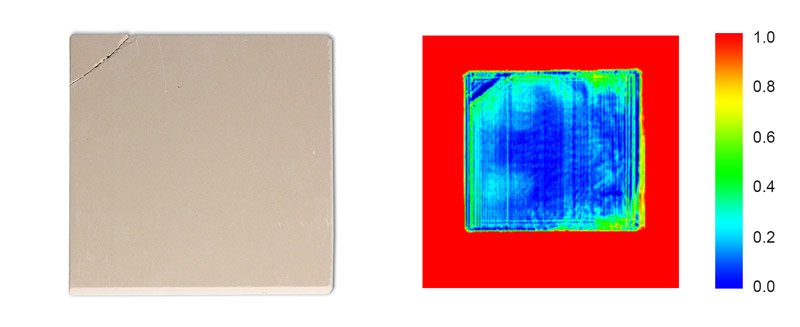

Pic.2 THz transmission image of a cracked 'green' tile with moisture gradient 1.5 - 2.2%. Cracks, hidden defects and moisture gradient of the tile are clearly detectable.

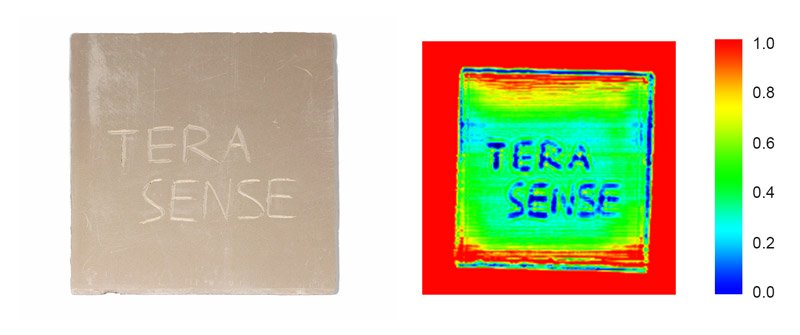

Pic.3 THz transmission image of a tile with scratched text on it. Scratched text, being a non-uniform surface, shows lower transmission in THz image due to scattering properties of the terahertz radiation.

Pic.3 THz transmission image of a tile with scratched text on it. Scratched text, being a non-uniform surface, shows lower transmission in THz image due to scattering properties of the terahertz radiation.

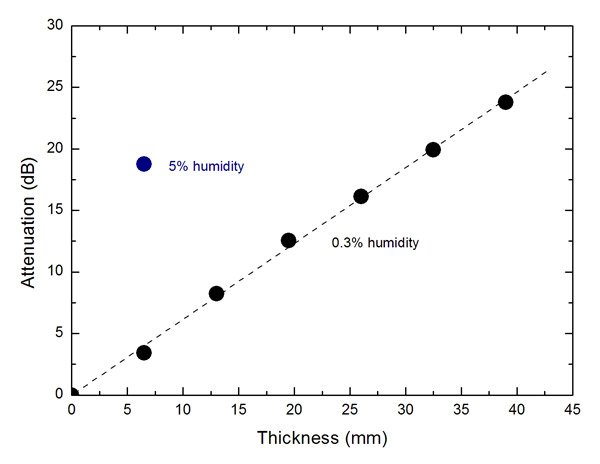

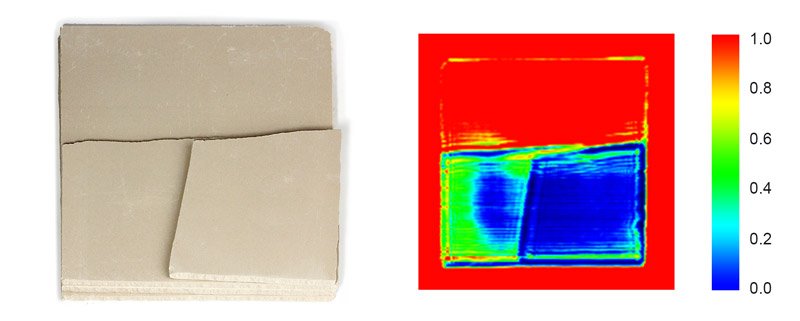

Pic. 4 THz transmission image of 13 mm, 19.5 mm and 26 mm thick ceramic tile (2, 3 and 4 layers of 6.5 mm ceramic tile accordingly).

Pic. 4 THz transmission image of 13 mm, 19.5 mm and 26 mm thick ceramic tile (2, 3 and 4 layers of 6.5 mm ceramic tile accordingly).