High speed linear terahertz scanner system is used for analyzing efficiency of optical & THz infrared thermography in NDT of GFRPs

Glass Fibre Reinforced Polymer (GFRP) is a modern engineering material which is highly versatile in nature. Two of its merits stand out a bit more from the rest of its attractive properties. As usual, on the one hand it is high strength and durability and on the other hand it is light weight of the material. Owing to these properties GFRP is commonly used in manufacturing water tanks, cooling tower bodies, washing machine bodies, windmill blades, aircraft parts, spacecraft parts, automobile parts, roofing sheets and in many other fields.

Glass Fibre Reinforced Polymer (GFRP) is a modern engineering material which is highly versatile in nature. Two of its merits stand out a bit more from the rest of its attractive properties. As usual, on the one hand it is high strength and durability and on the other hand it is light weight of the material. Owing to these properties GFRP is commonly used in manufacturing water tanks, cooling tower bodies, washing machine bodies, windmill blades, aircraft parts, spacecraft parts, automobile parts, roofing sheets and in many other fields.

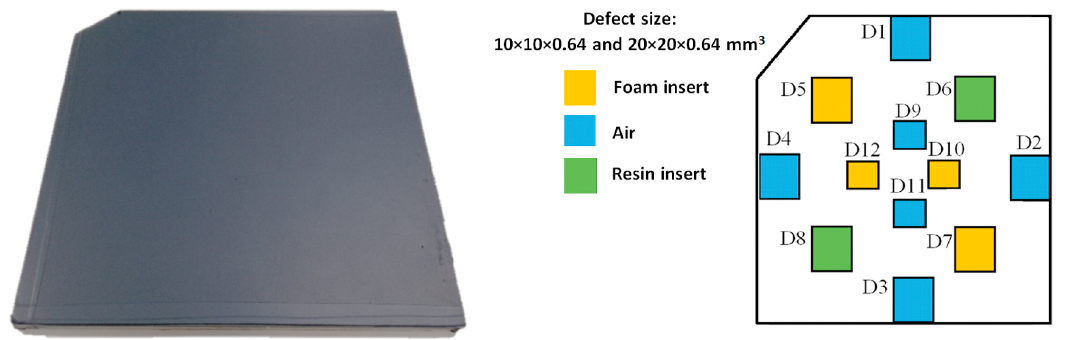

Of course, nothing is perfect and GFRP can also has its internal defects, inserts inclusions, anomalies, you name it that needs to be detected. No wonder that various techniques of non-destructive testing (NDT) of such useful material is gaining moment with respect to many industries that employ it. In its turn it prompts numerous research activity and experiments, which is usually followed up with its combative analysis. In this view we would like to put into spotlight one particular article entitled ‘Analyzing efficiency of optical and THz infrared thermography in nondestructive testing of GFRPs by using the Tanimoto criterion’ which was printed in NDT&E International journal that is a part of Elsevier, a world-wide known wealth of scientific knowledge.

In a nutshell, as it follows from its title, this study illustrated the capabilities of optical and THz infrared thermography in the detection of various inserts of different nature inside a solid piece of GPRP material. The NDT inspection efficiency of five different NDT techniques was evaluated and compared by applying the Tanimoto criterion. However, what makes us at Terasense take special pride about this comparison is that THz line-scanning procedure proved to rank among the best, finishing neck-to-neck with such other runner-ups as one-sided stationary thermal nondestructive testing (TNDT) implementing optical heating with Xenon lamps and optical scanning.

The research was conducted jointly by National Research Tomsk Polytechnic University, RF; I2M UMR CNRS-ENSAM-UB 5295, France; and Advanced Systems Laboratory, India. Well, another ‘feather in Terasense cap’ is that all three educational/research institutions are high profile Terasense customers and we used to closely interacted with their representatives when they were acquiring our THz imaging cameras, terahertz generators and high speed THz imaging system with appropriate linear optics.

The research was conducted jointly by National Research Tomsk Polytechnic University, RF; I2M UMR CNRS-ENSAM-UB 5295, France; and Advanced Systems Laboratory, India. Well, another ‘feather in Terasense cap’ is that all three educational/research institutions are high profile Terasense customers and we used to closely interacted with their representatives when they were acquiring our THz imaging cameras, terahertz generators and high speed THz imaging system with appropriate linear optics.

A

If we dig a bit deeper, we will notice that the researchers used our 100GHz high speed liner scanner system with pixle pitch 1.5mm and really impressive image acquisition rate (imaging speed up to 5000 lines per second that translates into 15m/sesond or 900m/minute).

In particular the authors of the article came to conclusion that the results obtained by using the terahertz line-scanning method looked less noisy and more sensitive to the structure of the sample (which was attributed to a higher resolution of the transducer). A special motorized stage enhanced with line-motion system was used to move the sample (a piece of GFRP) at a very low speed of 15 mm/s for elaborate scanning.  The system resolution along the detector direction was 0.68 pixel/mm, and in the perpendicular direction - 33 pixel/mm (THz pulse frequency 500 Hz),

The system resolution along the detector direction was 0.68 pixel/mm, and in the perpendicular direction - 33 pixel/mm (THz pulse frequency 500 Hz),

A

It hardly makes sense to retell the whole article here, while it is always available for downloading at https://doi.org/10.1016/j.ndteint.2020.102383. Needless to say that we encourage all our fans and THz technology followers to read it first hand. After that we expect to get your questions together with your RFQs for our table top and light weight 2D THz imaging systems, as well as high speed 1D linear THz scanner systems optimized for industrial application on conveyors.