Pharmaceutical applications

The pharmaceutical industry is supposed to heal and cure, so it simply cannot afford using X-ray technology that emits ionizing radiation, which is knowingly detrimental to human and animal health. In this context, Terahertz rays and THz-imaging are unique and safe alternatives.

Many materials used in the pharmaceutical and cosmetics industries are fairly transparent in the terahertz spectrum. This makes our technology very attractive as a harmless and nondestructive testing (NDT) technique during the production of drugs, medical products, and diapers, etc.

Quality control in pill production

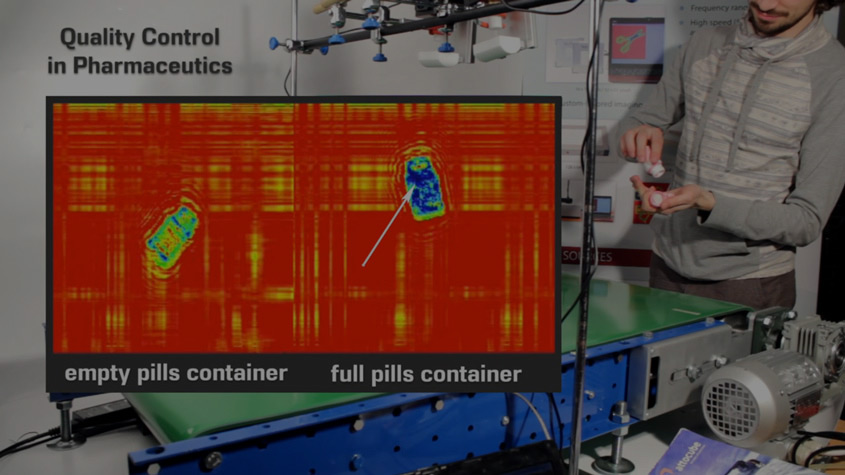

In the pharmaceutical and cosmetics industries, composites, paper, polyethylene (PE), and plastics and their derivatives are commonly used as packaging materials. Such materials have been proven to be fully transparent to THz rays, enabling our technology to identify missing items inside the packaging.

Due to human error, imperfections in existing production lines, and other factors, many pharmacy-related manufacturers badly need to make sure that every pouch in a tablet blister pack is properly filled, and that there are no empty blisters at the end of the process line. Likewise, it is important to check if quick-dissolving capsules have been properly filled with the active substance (reactant).

Another task is to check plastic pill-containers for fullness. Plastic containers are often intentionally manufactured to be opaque in visible light, while they remain perfectly transparent in the Terahertz spectrum and can be subjected to NDT inspection.

We have been getting many inquiries about using our THz imaging technology for applications in the pharmaceutical and cosmetics industries where X-rays are not acceptable for obvious reasons. Numerous questions from our customers prompted us to perform additional tests and collect and present our findings about feasible/suitable applications in these fields.

We encourage you to watch the video (by clicking on the link to the right), which shows how our THz imaging scanner handles NDT inspection of plastic containers with pills. Terahertz images obtained in our tests clearly show the difference between an empty plastic container and a full container. Needless to say, we used the same plastic container in both cases.

We would like to emphasize that our Terahertz scanner is not meant for counting the tablets, but it can perfectly distinguish between properly filled containers and insufficiently filled containers. Each packaging material is unique and should be checked, of course, but we believe our THz imaging technology is suitable for many types of packaging materials used in the pharmaceutical and cosmetics industries, except for those containing metal(e.g., metal foil).

Quality control in diaper production

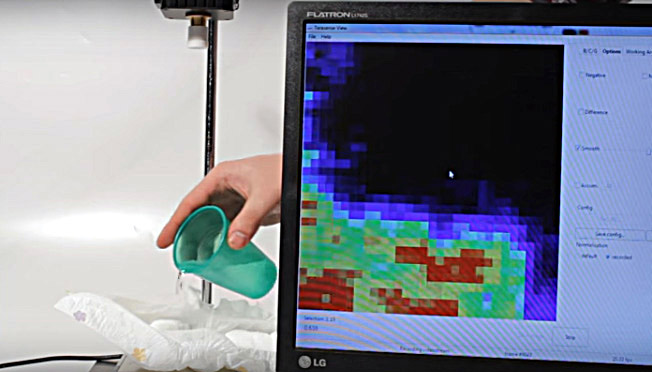

An important application associated with noncontact/noninvasive/nondestructive testing and quality control in the production environment is performing NDT of diapers to determine the presence of moisture, foreign bodies, or other contaminants.

We conducted an experiment with our «area» THz Imaging System aimed at determining water content in diapers. The video to the right shows how our THz camera can detect the presence of wet areas such as water and moisture in a diaper. Water creates a stark contrast in THz images and is therefore easily detectable. A liquid concentration gradient can be observed at the edges of the wet spot.

Even when the attenuation of water is very strong, it is possible to determine concentration differences. To measure the concentration differences of water within the wet spot, we simply increase the contrast in the settings of the TeraSense Viewer® Software and decrease the time resolution.

Quality control of in-stock items

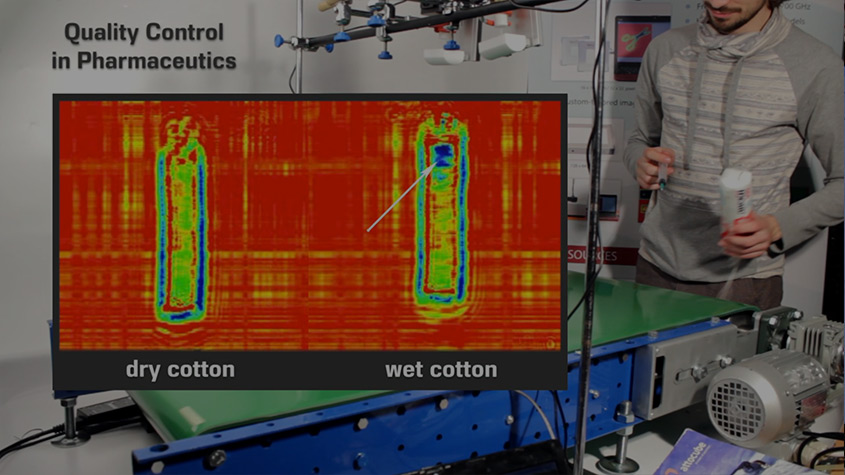

Tons of pharmaceutical and cosmetics products are stored for months at various warehouses before they finally reach customers. Depending on the storage conditions, the packaged items can be affected during that period, but it is difficult to tell what exactly is happening inside a package.

This is where the TeraSense THz imaging systems come in. The video (see the link to the right) shows how you can use our technology to check medical cotton for wet areas or check for moisture inside the package. Both the dry- and wet-cotton images were obtained from the same cotton pack. Wet area inside a package can be clearly identified in the THz image (see the wet-cotton image).

The TeraSense High-Speed Terahertz Imaging Scanner with operating speeds up to 15m/sec is a perfect tool for in-line quality control and NDT applications. POC (proof of concept) is readily available, and the number of applications for our THz imaging scanners in the pharmaceutical industry is growing each day. We cannot check and present here all potential applications. Our customers are welcome to contact us for more information.