NDT inspection for wood processing

A number of industrial NDT techniques like X-ray density scanning, infrared moisture sensors, visible light optical scanners and microwave kiln drying, employ separate parts of the electromagnetic spectrum to provide imaging of the wood in wood processing industry.

Despite the unique properties of the terahertz (THz) gap of the electromagnetic spectrum, THz imaging devices still do not top the list of wood-processing industrialists. For decades terahertz imaging systems were disregarded due to their high cost and slow speed, which precluded their adoption in real industry, thereby making way for other methods.

But the high speed, low cost THz imaging scanner solution from Terasense is now commercially available for industrial application so the situation is going to change rapidly! Every new step in the development of terahertz technology opens the door to many applications in a number of fields associated with the WOOD PROCESSING INDUSTRY, some of which are outlined below.

|  |

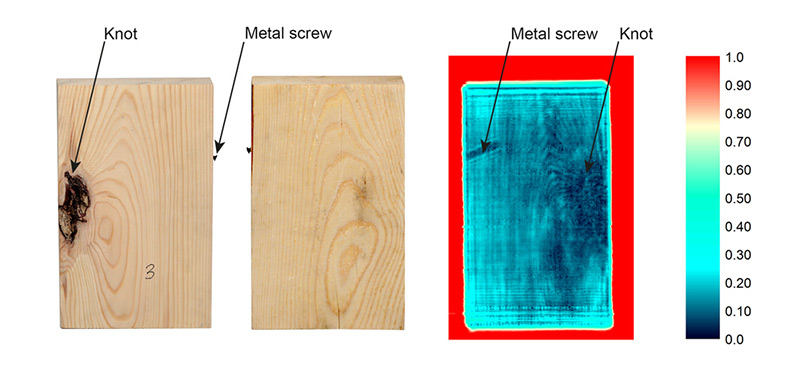

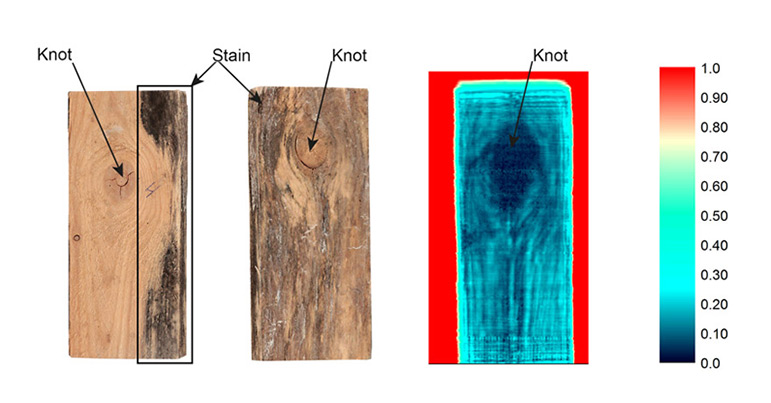

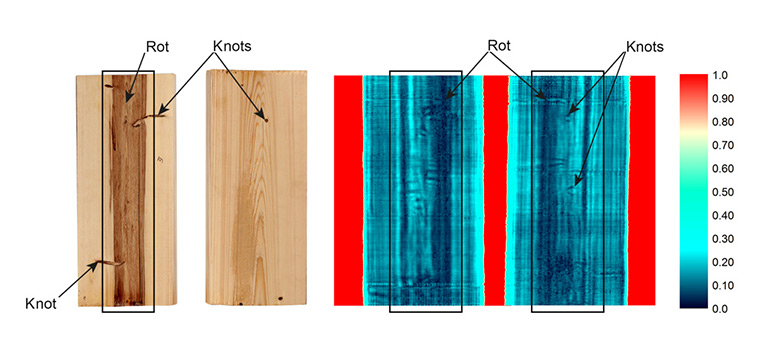

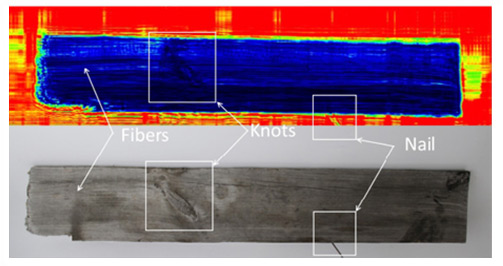

| THz images of wooden boards | |

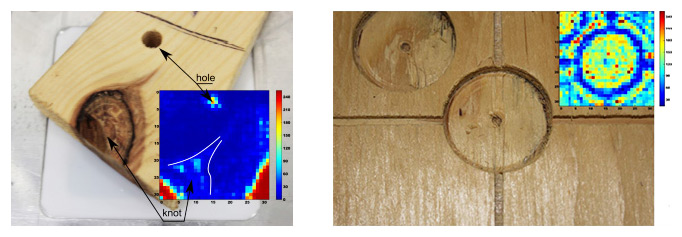

Detection of hidden defects in wood, (which are difficult to detect using other technologies, e.g., color vision) is the first that comes to mind. Such defects may include, but are not limited to, knots, hollows, and foreign bodies like nails, screw and wormholes, as well as wet areas. Some rots don’t produce color contrast, but the birefringence of rot is much lower than the wood around it, which allows detection in the THz spectrum.

Our THz technology can detect inhomogeneous areas (defects or foreign bodies), which differ from the surrounding area in one or more aspects, viz. density, thickness, moisture content etc. This property of T-rays allows us to differentiate substances based on their absorption/transmission data (rather than their spectroscopic data). This is why our THz camera can detect rot and wormholes inside the wood, which opens up additional opportunities for quality control or sorting.

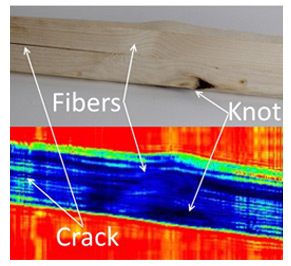

In fact, wood is one of the best materials for THz imaging. The polarization state of THz radiation is sensitive to fibrous structures, which provides more information about the substance than x-rays.

Polarized radiation gives valuable information about internal fiber patterns.

| |

| Pine board (thickness = 2cm) | Plywood board (thickness = 12 mm) |

THz technology offers the capability of transmission imaging that in real time can probe the internal structure of a non-conductive dry material with sub-mm spatial resolution. THz imaging vividly demonstrates the ability to check the internal configuration of the wood and see all hidden grooves, hollows and air pockets.

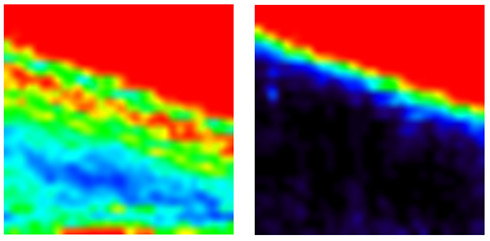

Other promising applications include detecting termites and other insects inside the wood and analyzing the wood for moisture content. The latter is a sure-fire method of determining wet areas inside a wooden log (or depending on the «grey scale», even estimating the volume of water inside the wood).

| |

| Dry wood board (14mm thick) | Wet Wood board |

THz imaging technology is essentially less invasive than X-ray technology. Terahertz radiation has no ionizing effect and is harmless to people and other living beings. There’s no need to use any of the restrictions and precautions that are obligatory for X-ray machines.

Its unique capability of harmlessly penetrating wood and its sensitivity to fiber structure makes terahertz technology ideally suited to applications in many wood processing fields, ranging from sawmills and lumbering to furniture production shops.

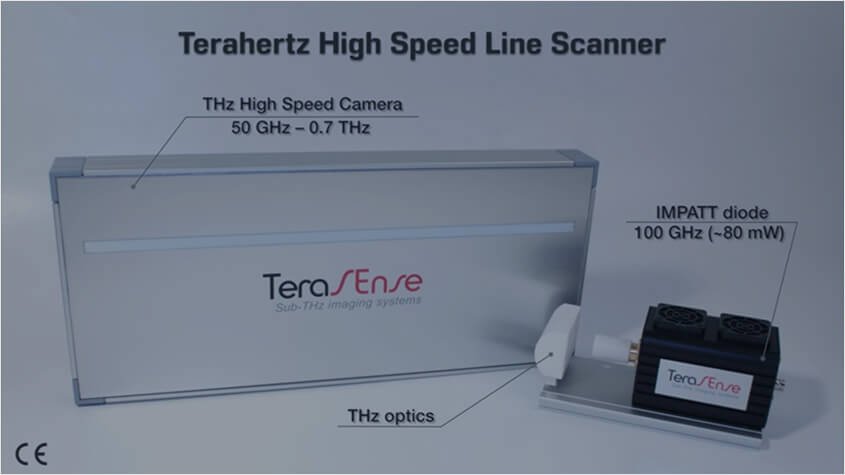

For a non-destructive test of wooden products, TeraSense offers a unique Terahertz High Speed Imaging Scanner which fits most conveyors with a belt running speed of up to 15 m/s.

Please watch our videos showing the performance of our Terahertz imaging scanner with wood.

Terahertz High Speed Line Scanner