Lecture notes 2 – Terahertz Non-Destructive Testing

In continuation of our series of short articles on terahertz technology, today we give a brief overview of Non-Destructive Testing (NDT) — the field where modern THz instrumentation has been applied most widely.

For the most part, terahertz NDT systems are designed to operate in transmission mode. Hence, they mainly consist of a generator (wave source), a detector (camera) and supplementary beam-shaping optics.

In practice, THz scanners can be used effectively for introscopy — examination of internal structure of an object, and for defectoscopy — detection of hidden defects. The latter method, in particular, has proven successful in various streamlined manufacturing industries as a tool for quality control of products made of materials such as, dielectrics, fiberglass, plastics, ceramics, etc., in which THz waves are attenuated weakly. On a technical note, when integrated into a conveyor line in industrial applications, THz scanner requires a special kind of conveyor belt made of materials transparent to THz radiation, such as PVC, polyester, rubber or composite material without carbon black pigment.

The following two tables give examples of some common homogeneous materials and every-day items with layered structure along with their attenuation coefficient and transmittance in the THz band.

TABLE 1: Attenuation coefficient of some common homogeneous materials:

Material | (cm-1) @ 0.5 THz | (cm-1) @ 1 THz |

Plastic glass | 1.6 | 3.8 |

Polystyrene foam | <0.02 | <0.04 |

Glass | 7 | ~8 |

Quartz | 1.9 | 3.5 |

Pottery | 6.3 | - |

Tile | 4.5 | 7 |

Stone | 2.5 – 5.8 | 4.6 – 8.5 |

Wood | 2.6 – 6.2 | > 3.5 |

Brick | 4.5 | 8 |

Concrete | 4.7 | 9 |

Water | 150 | 220 |

Chloroform | 17 | 16 |

Toluene | 1 | 3 |

Oil | 3.7 | 9 |

TABLE 2: Transmittance of common items composed of layered materials:

Item | Description | Trans % | Trans layers | Trans % @ 0.5 THz | Trans % @ 1 THz |

Leather glove | 2 layers, 1mm/layer | 4 | 7 | 3.2 | 2.8 |

Coat | 1 layer, 5 mm | 14.7 | 6 | 22.8 | 3.8 |

T-shirt | 1 layer, 0.5 mm | 87.5 | 86 | 87.4 | 70.6 |

Down | 3.7 | 3 | 5.7 | 1 | |

Sweater | 1 later, 2 mm | 21.6 | 7 | 40.8 | 1.9 |

Socks | 2 layers, 2mm/layer | 26.7 | 8 | 35.5 | 13.2 |

Slippers | Bottom, 15 mm | 0.4 | 2 | 0.04 | 0.1 |

Towel | Cotton, 1.5 mm | 45.6 | 14 | 65.9 | 19.8 |

Wallet | Half part, empty | 9 | 4 | 18.3 | 0.6 |

Laptop bag | Whole bag | 3 | 3 | 4.1 | 0.8 |

Cloth bag | 2 layers | 68.7 | 60 | 64.6 | 79.2 |

CD bag | Empty | 5.6 | 4 | 10 | 0.7 |

Card board | 2.1 mm | 62.5 | 24 | 53.7 | 9.2 |

Carpet | 3 mm | 56.7 | 20 | 35.5 | 0.3 |

Plastic floor | 2.5 mm | 70.3 | 32 | 52.6 | 11.6 |

Bubble plastic | 4 layers | 68.8 | 32 | 81.9 | 49.8 |

Mouse pad | 3 mm | 48.9 | 16 | 74.7 | 18.9 |

Floppy disk | - | 15.4 | 6 | 9.6 | 20 |

Presently, state-of-the-art industrial NDT schemes entail highly-portable and easily operated systems capable of rapid scanning, at conveyor speeds of 500 mm/sec and above — all of which necessitates such key features of a THz scanner as:

- Compactness

- Low cost

- High-power source

- High acquisition rate camera capable of real-time imaging.

To meet these requirements, TeraSense has developed a new High-speed linear scanner as a robust and reliable solution for real-time 2D imaging of flat objects.

Compared to conventional X-ray imaging, TeraSense linear scanner has several significant advantages listed in Table 3 below. Furthermore, X-ray systems are absolutely incapable of detecting clothes, plastic, wood and paper, whereas THz technology enables good-quality contrast imaging of these materials, which makes it the only practical solution for their structural analysis.

TABLE 3: Advantages of a new THz linear scanner over the X-ray technology:

TeraSense THz scanner | X-ray imager | |

Safety | 100% safe | Ionizing radiation hazard |

Entry level price | ~ $25,000 | ~ $70,000 |

Conveyor speed | Up to 15 m/s | ~0.2 m/s |

Special permits | Not required | Required |

Another aspect of NDT to consider is the spatial resolution of a THz camera. This parameter is inversely proportional to the operating wavelength of the imaging system. Thus, our currently available linear scanners provide lateral resolution of 3 mm at 100 GHz and 1 mm at 300 GHz. Importantly, when choosing operating frequency, it is critical to take into account the fact that attenuation of THz waves increases exponentially from 100 GHz to 300 GHz. However, as a possible way of overcoming the attenuation problem at 300 GHz, TeraSense has devised a new, more powerful 280 GHz wave source with output CW signal of 40 mW. Because of its compact packaging, this generator can be either used as a standalone unit or integrated easily into any scanner system with the same operating frequency to boost its imaging performance.

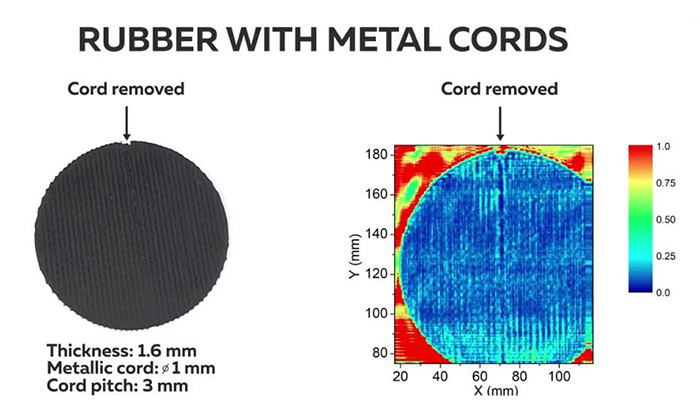

Finally, to demonstrate the capability of TerSense linear scanner to detect a flaw in NDT product quality control, below we show an inspected rubber sample with internal metal cords, and its scanned THz image. As indicated in the middle part of the THz picture, there is a clearly visible defect — a missing cord.