New application of the High Speed THz Linear Scanner

We all know how important quality control in production is. However, in some circumstances carrying it out in conventional ways may not be possible. In door fabrication, for instance, controlling the quality of PU foam filling the space between plastic surfaces is no trivial matter. Using an elaborate X-ray system is unduly hazardous and overly expensive. Besides, it yields a low contrast image. On the other hand, resorting to a simple and direct method of cutting every 1000th door open is not only time-consuming, but also gives no 100% quality guarantee. It is for such nontrivial cases that TeraSense offers an elegant reliable and cost-effective solution: the High Speed THz Linear Scanner!

We all know how important quality control in production is. However, in some circumstances carrying it out in conventional ways may not be possible. In door fabrication, for instance, controlling the quality of PU foam filling the space between plastic surfaces is no trivial matter. Using an elaborate X-ray system is unduly hazardous and overly expensive. Besides, it yields a low contrast image. On the other hand, resorting to a simple and direct method of cutting every 1000th door open is not only time-consuming, but also gives no 100% quality guarantee. It is for such nontrivial cases that TeraSense offers an elegant reliable and cost-effective solution: the High Speed THz Linear Scanner!

So far Terahertz technology has made its way into various applications in healthcare, agricultural production, ceramic and automotive industries, security, pharmaceutical industry and food production, etc. This long list has now been extended to include the field of Non Destructive Testing (NDT) of plastic objects.

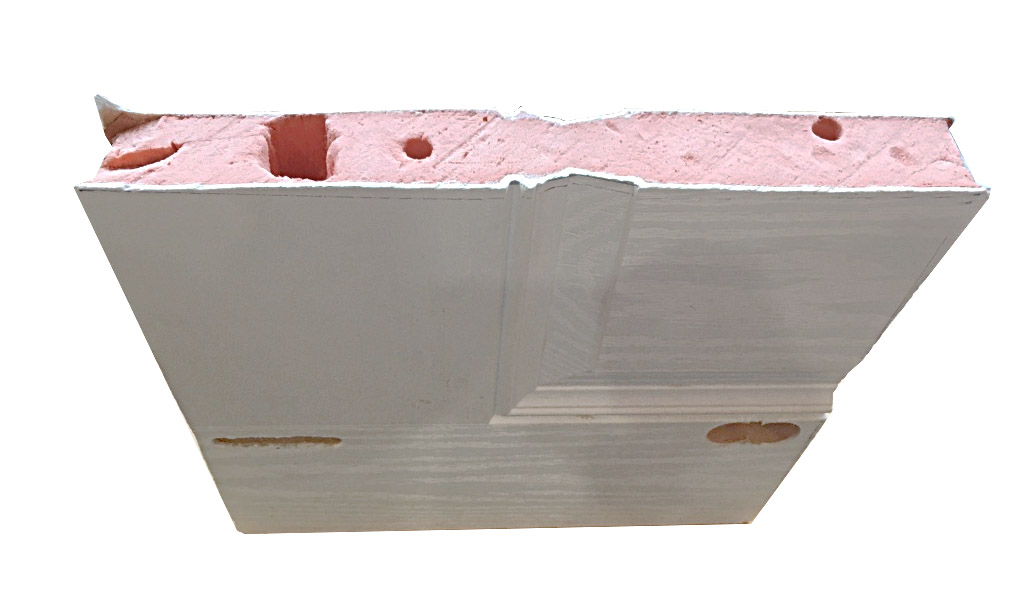

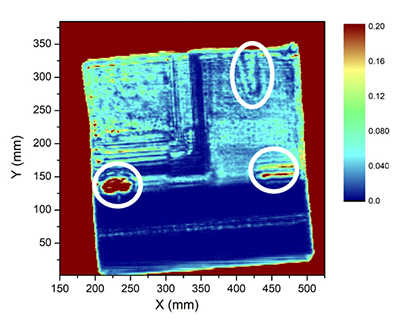

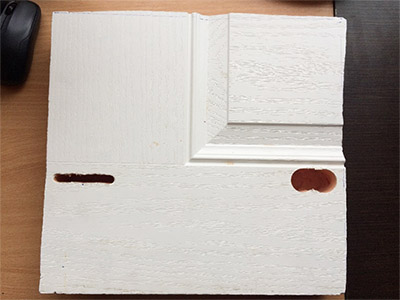

At the request of our partner in Asia, we have recently investigated the viability of Terahertz technology in this particular area. The results have been very encouraging since plastic, PU foam and dry wood have little absorption at THz frequencies and are virtually transparent to THz radiation. In our experiments we used 100GHz High Speed Linear Scanner with 1,5mm spatial resolution to detect voids in PU foam and in fiberglass skin. The resultant THz image shows all hidden internal defects which are fully detectable. This THz NDT method can be used not only for quality control in door production, but also for testing any flat plastic panels or wooden parts. To meet customer demand for even higher spatial resolution, TeraSense offers its 300GHz High Speed Linear Scanner capable of detecting defects as small as 0,5mm in size.

TeraSense High Speed Linear Scanners consist of two parts: a High Speed Linear Camera (usually placed under the conveyor) and a THz wave source equipped with special mirror system that shapes radiation beam into a narrow strip. The entire system is compact and easy to install. It is operated with special TeraSense software that can be installed on any PC.

Growing global popularity of Terahertz technology makes us look into the future with great optimism as we carry on developing new applications for life, science and industry.