Terahertz applications in ceramic industry

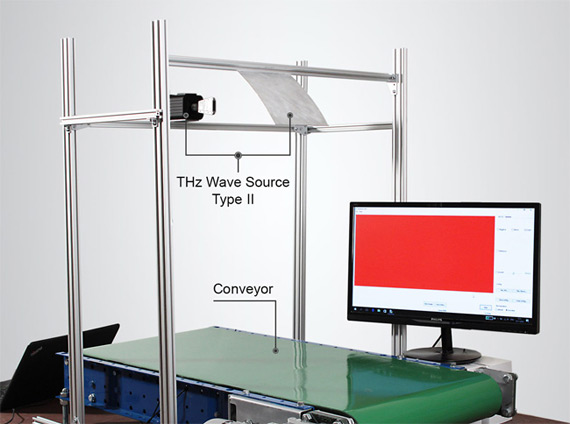

The high speed linear terahertz scanning system manufactured by TeraSense for conveyor belt applications is a perfect solution for non-destructive test and quality control of various materials in an industrial environment. One of the key benefits of the TeraSense THz imaging technology is its high sensitivity to multiple features and inclusions in the volume of non-metallic materials (ceramics, plastics, wood). One of the most notable applications of the system is an evaluation of density and humidity variations in pressed powders (‘green tiles’ and kiln fired tiles in the ceramic industry; pills, caplets, and tablets in the pharmaceutical industry, etc.).

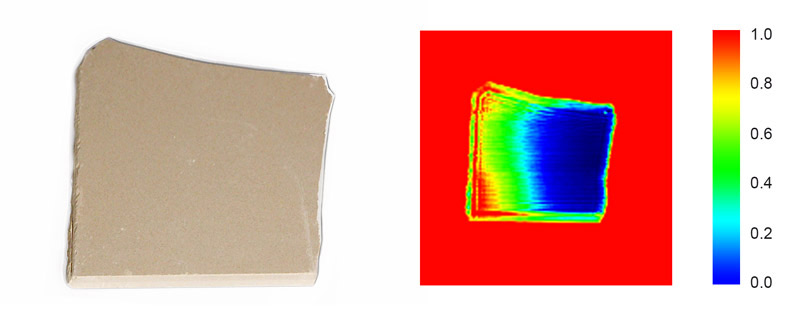

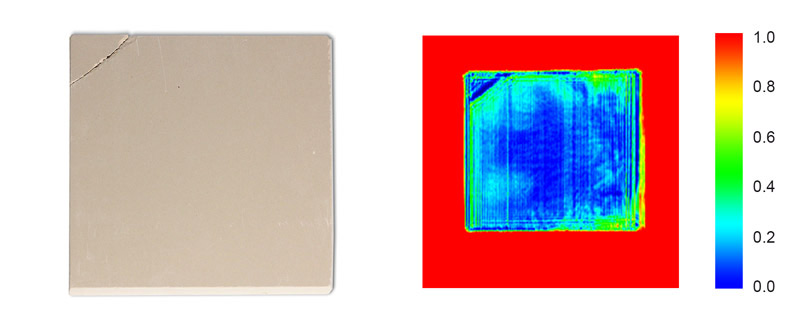

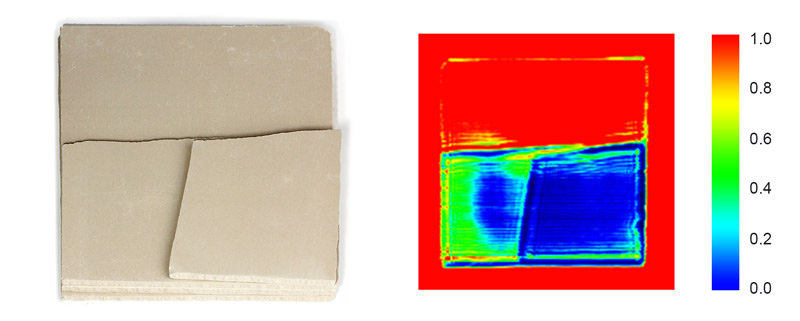

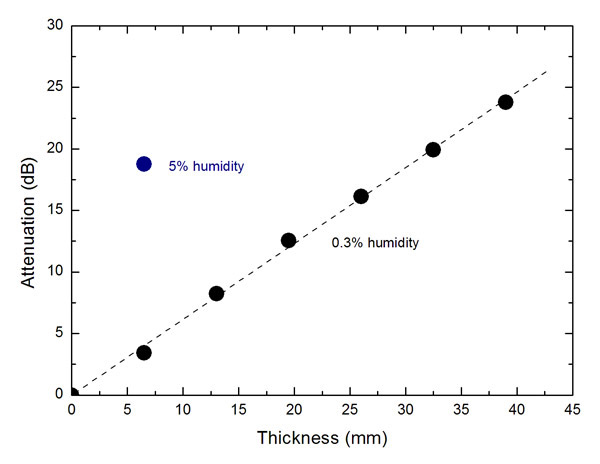

One of the important aspects in the ceramic tile industry is to monitor density gradients in ‘green’ tiles right after their being formed in a press and examine finished tiles for various defects. Unlike x-ray technology, the TeraSense THz imaging is highly sensitive to density deviations and especially to moisture content of ceramic samples. The TeraSense technology is your instrument to monitor density deviations in a tile right from the forming press and to provide feedback for a powder feeding machine.

Advantages of the THz imaging system

with Type II sub-THz Source.

Extremely high image acquisition rate (up to 5000 fps)

Non-destructive (no ionizing radiation)

Powerful tool for inspection of defects in dry tiles

Powerful tool for measuring density or humidity variations in wet tiles

Low cost solution

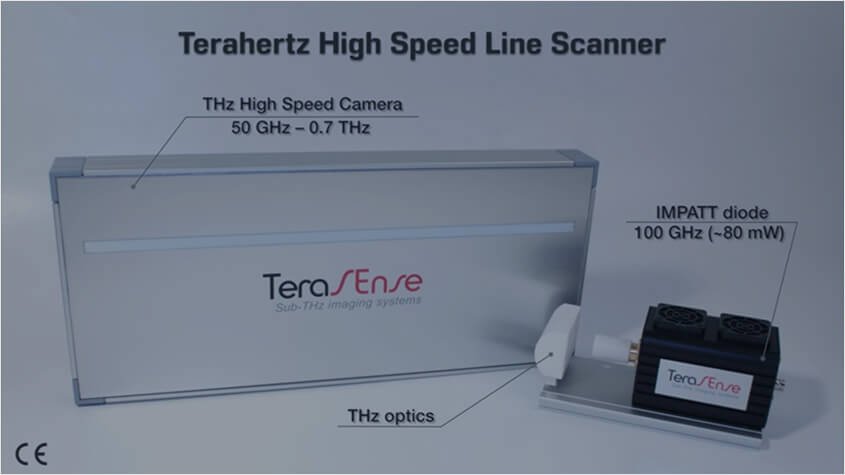

Basic specifications of the system Type II

Camera

- Operation frequency: 100 GHz

- Image acquisition rate: up to 5000 lines per second

- Image width and number of pixels: custom (typical 384 x 3 mm2, 256×1 pixel)

- Pixel pitch: 1.5 mm

- Spatial resolution: 3 mm

- Fits conveyor belt running speed up to 15 m/s

- Original software: TeraFast® Viewer

- Interface: mini-USB

- Power supply: 24V / 20W

Source

- Operation frequency: 100 GHz

- Power per camera pixel: 140 µW

- Reflection beamforming optics

- Protective isolator for enhanced stability

Defect detection and humidity measurements

by factory tests

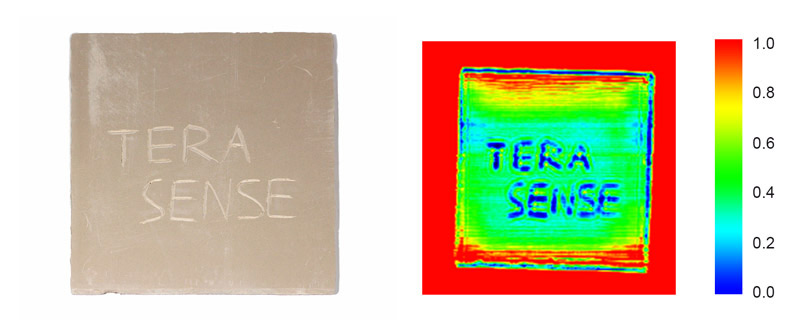

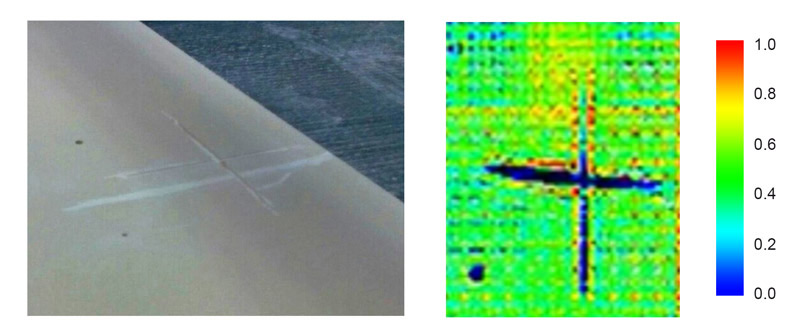

TeraSense TeraFAST imaging system can detect various defects, such as:

- Cracks

- Holes, voids D > 3 mm

- Scratches > 3 mm deep

- Inclusions (especially metallic)

and moisture gradient of the tile are clearly detectable.

Imaging of defects in ceramic tiles